A qualified wholesale geotextile supplier plays a pivotal role in large-scale construction and environmental engineering. Demand for geosynthetics continues to rise as global infrastructure development accelerates and sustainability requirements increase. The reliability of the geotextile supply chain can directly influence ground stability, drainage efficiency, engineering costs, and long-term durability of civil works.

Proper understanding of product selection and supplier capability is therefore essential for engineers, contractors, and procurement managers.

Why Geotextiles Are Critical to Modern Engineering Needs

Geotextiles are engineered to improve soil behavior while reducing construction complexity. These permeable reinforcement materials enable safer and more cost-efficient development in challenging ground conditions.

Common engineering benefits include:

• Reducing soil settlement and structural failure

• Enhancing load distribution on weak foundations

• Providing filtration and drainage for groundwater control

• Preventing erosion along slopes, riverbanks, and coastlines

• Lowering the amount of traditional aggregate required

As a foundational layer, geotextiles support long-lasting performance of roads, tunnels, dams, landfills, retaining structures, and more.

Key Functions Required in Civil Engineering Projects

• Separation — Prevents aggregate contamination and preserves structural integrity

• Reinforcement — Improves soil tensile strength to handle heavy loads

• Filtration — Allows water to pass while retaining fine soil particles

• Drainage — Controls hydraulic pressure in subgrade layers

• Protection — Shields geomembranes and other underground structures

• Erosion Control — Prevents soil loss due to flowing water and wind

These multi-functional roles make geotextiles indispensable in professional geotechnical solutions.

Advantages of Sourcing from a Reliable Wholesale Geotextile Supplier

Bulk procurement from an established supplier helps ensure engineering success through:

• Stable, standardized material performance

• Efficient cost control for major procurement plans

• Diverse catalog including woven, nonwoven, and composite products

• Availability of engineering documentation and test certifications

• Timely delivery suited to infrastructure scheduling

• Customizable GSM, dimensions, packaging, and installation specifications

• Long-term lifecycle value through reinforced ground structure stability

The assurance of quality and continuity in supply ultimately reinforces asset longevity.

Product Categories Commonly Provided by Wholesale Geotextile Suppliers

Woven Geotextile

• High tensile strength for reinforcement and load spreading

• Ideal for highways, container yards, and industrial foundations

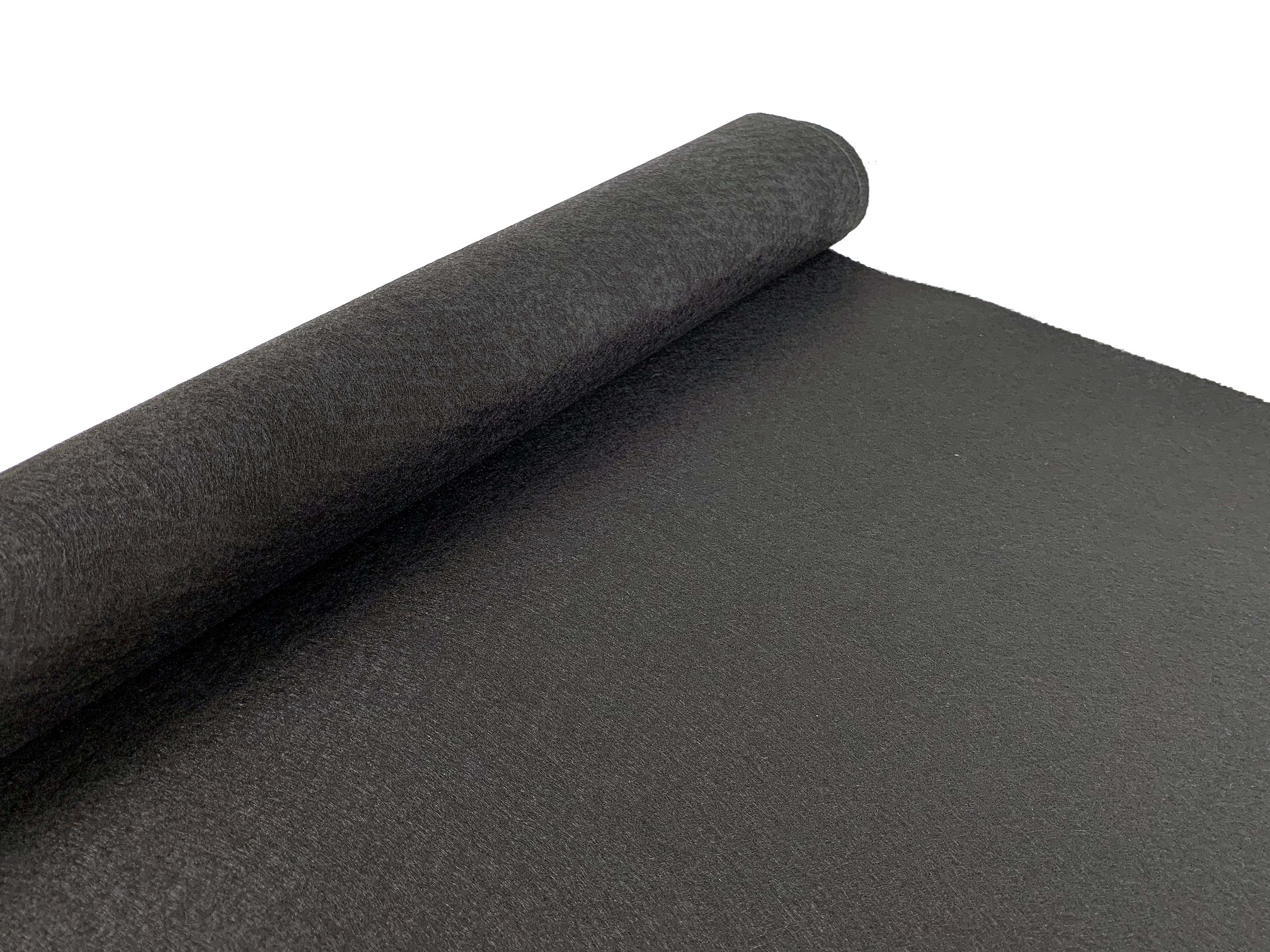

Nonwoven Geotextile

• Excellent filtration and drainage characteristics

• Widely used in landfills, drainage systems, and tunnel waterproofing

Composite Geotextiles

• Integrated functions for multi-layered ground systems

PP vs PET Material Characteristics

• PP: chemically resistant, suitable for marine and sewage environments

• PET: long-term creep resistance for sustained loading conditions

Precise selection depends on soil type, structural requirements, hydraulic behavior, and environmental exposure.

Application Fields with Rapid Market Growth

• Road and railway expansion

• Coastal protection and flood prevention

• Mining haul roads and tailings containment

• Urban drainage and pipeline corridor development

• Renewable energy infrastructure platforms

• Ports, airports, and industrial facilities

• Water conservancy and environmental remediation

As demand for climate-ready infrastructure increases, geotextile usage continues to expand across continents.

Quality and Compliance Standards Essential for Global Procurement

Performance consistency and regulatory approvals are critical evaluation criteria. Important metrics include:

• Tensile strength and CBR puncture resistance

• Permeability and pore size uniformity

• Resistance to UV exposure and chemical reactions

• Fiber bonding density and dimension accuracy

• ISO / ASTM / CE certifications supporting government project requirements

• Tracking documentation for engineering audits and tenders

Validated quality offers predictable results in demanding environments.

Innovation and Sustainability Trends Shaping Geotextile Production

Modern geotextile manufacturing increasingly incorporates:

• Energy-saving and low-emission production lines

• Recyclable raw materials to reduce environmental burden

• Extended UV endurance for outdoor and tropical climates

• Enhanced filtration precision to protect soil-water ecosystems

• High durability to minimize repair frequency and lifecycle waste

These innovations align with global ESG and infrastructure resilience goals.

Summary

A dependable wholesale geotextile supplier supports the successful construction of highways, railways, coastal works, drainage systems, and land stabilization projects. When selecting a supplier, technical specifications, verified quality, logistics dependability, and product diversity all contribute to long-term project value.

As public and private sectors invest in durable and sustainable infrastructure, geotextiles will remain essential to modern civil engineering development worldwide.

FAQ

Q1: Which industries rely heavily on wholesale geotextile supply?

Applications span road construction, mining, water conservancy, waste management, and coastal infrastructure.

Q2: Can geotextiles be customized to specific engineering requirements?

Dimensions, strength ratings, GSM, roll lengths, and environmental resistance features can be fully tailored.

Q3: How can quality be verified in international sourcing?

Check tensile performance, permeability tests, certified QC systems, and engineering compliance reports.

Q4: Why are nonwoven geotextiles widely used for filtration and drainage?

Their needle-punched fiber structure allows water flow while preventing soil migration, improving foundation stability.

Post time: Dec-05-2025