In modern construction, civil engineering, and environmental projects, geotextiles play a critical role in soil stabilization, erosion control, and drainage management. Among the most commonly used types are polypropylene (PP) geotextiles and PET (polyester) geotextiles. Understanding the differences between these materials is essential for businesses in construction, landscaping, and infrastructure sectors to make informed decisions about which geotextile to select for their projects.

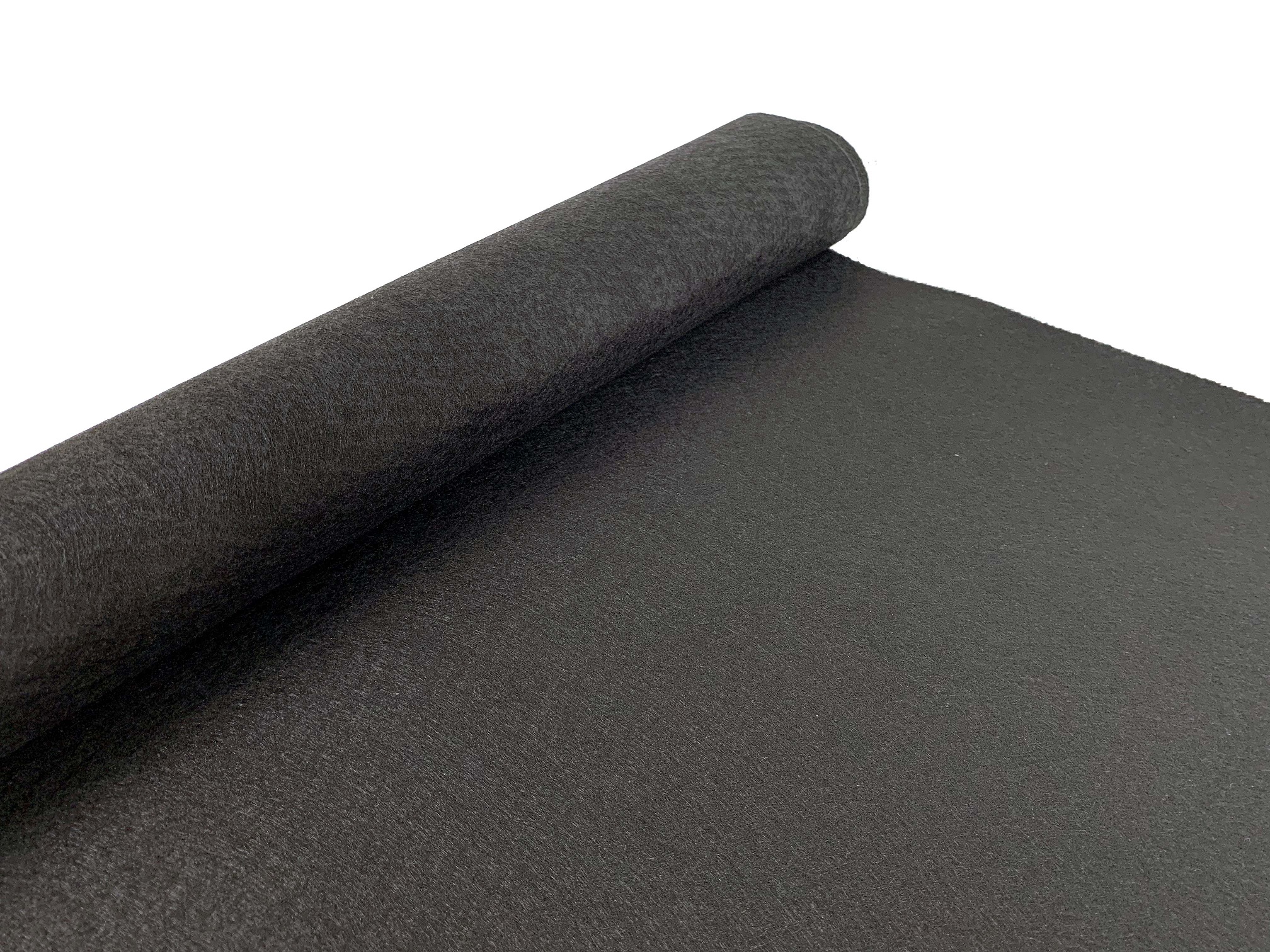

What is Polypropylene (PP) Geotextile?

Polypropylene geotextiles are synthetic fabrics made from thermoplastic polypropylene fibers. They are typically manufactured as woven or non-woven fabrics, offering high tensile strength, lightweight properties, and excellent chemical resistance. PP geotextiles are widely used in applications where cost-effectiveness, water drainage, and soil separation are required.

Key characteristics of PP geotextile include:

● Lightweight – Easier to handle and transport, reducing installation costs.

● Hydrophobic – Resistant to water absorption, allowing efficient drainage.

● Chemical Resistance – Can withstand most acids, bases, and alkalis commonly found in soil and construction environments.

● UV Resistance – Suitable for outdoor applications with moderate exposure to sunlight.

What is PET (Polyester) Geotextile?

PET geotextiles, made from polyester fibers, are usually produced as woven fabrics. They are known for superior tensile strength and dimensional stability, making them ideal for heavy-duty construction projects. PET geotextiles are often selected for infrastructure works, including roads, highways, embankments, and reinforcement projects where long-term durability and high load-bearing capacity are critical.

Key characteristics of PET geotextile include:

● High Tensile Strength – Can support heavy loads and resist deformation.

● Excellent Creep Resistance – Maintains performance under long-term stress and weight.

● Durability – Resistant to environmental degradation, UV exposure, and most chemical interactions.

● Dimensional Stability – Ensures consistent performance over time, especially under heavy traffic or soil pressure.

Key Differences Between Polypropylene and PET Geotextiles

Understanding the main differences helps engineers, contractors, and procurement managers choose the right geotextile for their specific needs:

● Material Strength – PET geotextiles typically offer higher tensile strength and creep resistance compared to polypropylene, making them suitable for heavy-load applications. PP geotextiles are lighter and may be preferable for moderate-load projects.

● Durability – PET fabrics are more resistant to long-term environmental degradation, including heat and UV exposure, whereas PP fabrics may degrade faster under extreme conditions.

● Weight and Handling – PP geotextiles are lighter, easier to handle, and often more cost-effective to install. PET fabrics are heavier due to their denser weave and higher fiber strength.

● Applications –

● PP geotextiles are ideal for soil separation, drainage systems, erosion control, and landscaping projects.

● PET geotextiles are better suited for road construction, embankment stabilization, landfill reinforcement, and other heavy-duty engineering applications.

● Cost – PP geotextiles are generally more affordable, making them a popular choice for projects with budget constraints. PET geotextiles have a higher initial cost but deliver superior performance and longevity in demanding applications.

Choosing Between Polypropylene and PET Geotextiles

Selecting the right geotextile depends on project requirements:

● Load Requirements – For high-traffic areas or heavy structures, PET geotextiles are recommended. For moderate loads, PP geotextiles may be sufficient.

● Environmental Conditions – Consider exposure to UV, chemicals, or moisture. PET geotextiles perform better in harsh conditions.

● Budget Constraints – PP geotextiles provide cost-effective solutions without compromising basic performance.

● Installation Ease – PP geotextiles are lighter and easier to transport and lay down on-site.

Conclusion

Both polypropylene and PET geotextiles serve critical functions in modern construction and environmental management. PP geotextiles excel in lightweight, cost-effective, and moderate-load applications such as drainage and soil separation, while PET geotextiles offer superior tensile strength, durability, and creep resistance for heavy-duty engineering projects. Understanding the differences allows B2B buyers, contractors, and engineers to select the most suitable geotextile material, ensuring safety, efficiency, and long-term project performance.

FAQ:

Q1: Can PP geotextiles be used for road construction?

PP geotextiles are generally suitable for light to moderate load areas, but PET geotextiles are preferred for heavy-duty roads and highways.

Q2: How long do PET geotextiles last compared to PP?

PET geotextiles typically last longer due to better creep resistance and environmental durability, making them ideal for long-term infrastructure projects.

Q3: Are polypropylene geotextiles environmentally friendly?

Yes, many PP geotextiles are recyclable, and some manufacturers offer biodegradable options for sustainable construction.

Q4: Can PP and PET geotextiles be combined in a project?

Yes, in some projects, engineers may use PP geotextiles for drainage layers and PET geotextiles for structural reinforcement to optimize cost and performance.

Post time: Jan-26-2026