Geotextiles play an increasingly important role in improving the safety, performance, and environmental durability of infrastructure projects. For B2B buyers such as importers, distributors, and engineering contractors, working with a cost-effective geotextile factory is the best way to maintain strong profitability while ensuring technical reliability in the field. As a professional geotextile supplier, we are committed to supporting global construction with value-driven, dependable material supply.

Why Geotextiles Matter in Modern Civil and Environmental Engineering

Geotextiles are widely used in road construction, railway systems, landfills, tunnels, erosion control structures, agricultural facilities, mining operations, and industrial foundations. Their functions include soil separation, reinforcement, filtration, drainage, and environmental protection. When selected properly, geotextiles enhance load-bearing performance, stabilize soil layers, reduce maintenance costs, and extend the lifespan of geotechnical systems.

The global growth of infrastructure investment drives long-term demand for geosynthetics. This requires material suppliers who not only understand the technical standards but also support project delivery schedules through strong manufacturing and export capabilities.

What Makes a Cost-Effective Geotextile Factory a Better Partner

Geotextiles must ensure durability and performance under complex construction environments. If procurement focuses only on the lowest price, it may result in poor soil protection, premature structure failure, and costly repairs. Choosing a factory-level supplier allows buyers to achieve procurement efficiency while minimizing long-term engineering risk.

In addition, sourcing directly from a manufacturer enables close technical communication, streamlined logistics, and flexible customization. This is especially important for companies supplying multiple regions and project types.

What We Provide as a Cost-Effective Geotextile Factory Supplier

• Competitive pricing supported by efficient production and raw material sourcing

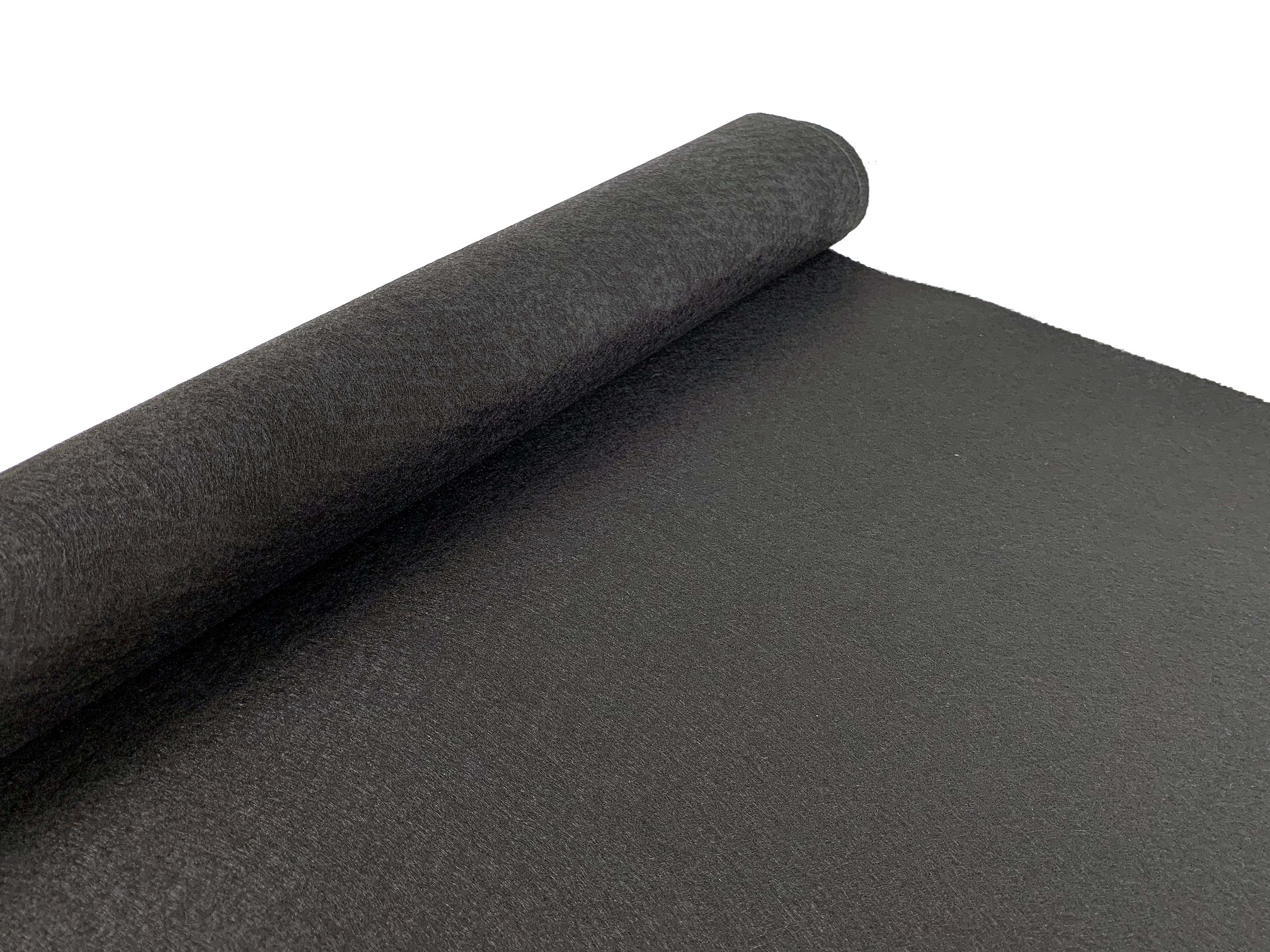

• A wide range of nonwoven and woven geotextiles for different engineering requirements

• Technical assistance for correct product selection to match soil and climate conditions

• Customized roll width, length, packaging, and branding to support B2B business models

• Stable delivery capacity for long-period infrastructure projects

• Support for third-party testing and compliance documentation

• Consistent quality backed by advanced QC systems

• Professional export coordination for global delivery

We support both large construction contractors requiring bulk materials and distributors developing local markets with ongoing and diversified demand.

Main Application Fields Across Global Infrastructure

• Road subgrade separation to prevent soil intermixing and deformation

• Railway ballast filtration and reinforcement for long-term operational stability

• Landfill containment systems ensuring protection of geomembranes

• Underground drainage and tunnel waterproofing support

• Coastal and riverbank reinforcement to mitigate erosion damage

• Agricultural soil improvement and irrigation efficiency enhancement

• Landscape engineering for slope stability and vegetation growth

• Industrial and mining foundation stabilization

As geological environments become more challenging, the performance requirements for geotextiles continue to rise. Stable material supply directly benefits engineering reliability and lifecycle cost control.

How to Evaluate a Reliable Cost-Effective Geotextile Factory

Conducting due diligence helps ensure your supplier is capable of long-term cooperation:

1.Review the factory’s testing capability, including mechanical properties and durability performance

2.Confirm material traceability and standard compliance requirements

3.Evaluate production capacity and ability to handle urgent or large-scale orders

4.Assess packaging and container loading quality for export shipment

5.Verify whether technical engineers can support specification recommendations

6.Ensure the supplier understands export procedures and documentation

7.Check consistency of performance through existing project references

A reliable manufacturer not only produces materials, but also helps customers make informed engineering decisions.

Technical Requirements for Performance and Durability

High-value geotextiles should provide:

• Sufficient tensile strength and elongation to resist soil movement

• Effective permeability to allow water flow while retaining soil particles

• Strong puncture and tear resistance suitable for heavy loading and burial conditions

• Aging and environmental resistance to maintain long-term stability

• Structural integrity under sustained or cyclic loads to prevent premature failure

Cost-effectiveness should never be defined by compromising these required technical attributes.

Why Direct Cooperation Improves B2B Procurement Value

Working with a geotextile factory supplier directly enhances supply chain competitiveness:

• Transparent pricing and cost structure

• Fast response time for urgent needs and specification adjustments

• Accurate alignment between design requirements and production plans

• Improved delivery reliability for multi-phase engineering projects

• Stronger negotiation and contract flexibility for long-term business

For distributors, a stable supply partner enables broader market coverage and customer retention. For contractors, it helps to secure competitive tendering opportunities while maintaining engineering safety.

Long-Term Strategic Cooperation Benefits

Infrastructure development is ongoing and continuous. Establishing reliable supply partnerships allows buyers to:

• Maintain pricing advantage in fluctuating material markets

• Avoid delays caused by supply disruptions

• Use consistent quality materials across multiple project locations

• Strengthen competitiveness for future procurement and tenders

A dependable manufacturer is a foundational asset in long-term construction planning.

Conclusion

Choosing a cost-effective geotextile factory is a strategic move for global infrastructure stakeholders who seek optimized procurement cost without sacrificing engineering reliability. As a supplier focused on value delivery, we support our partners with consistent performance, technical competence, and international logistics capabilities. Cost-effectiveness means maximizing the value of every investment, not merely reducing the material price.

We welcome distributors, engineering companies, and international procurement entities to collaborate with us for sustainable and scalable supply solutions in geotechnical construction.

Frequently Asked Questions (FAQ)

Q1: How can I be sure a geotextile factory has long-term supply capability?

Look for a manufacturer with strong equipment capabilities, proven delivery history, and a stable quality management system.

Q2: Why is working directly with a factory more beneficial than sourcing through traders?

Factories provide transparent technical support, clearer lead-time planning, and better control of product consistency.

Q3: What is the primary function of geotextiles in engineering projects?

Depending on the environment, they mainly perform separation, reinforcement, filtration, drainage, or environmental protection functions.

Q4: How can I ensure the geotextile supplied is suitable for the target application?

Suppliers should offer engineering recommendations based on soil type, loading conditions, and long-term durability requirements.

Post time: Dec-03-2025