In civil and environmental engineering, geotextiles have become a critical component in improving soil performance and ensuring the stability of large-scale infrastructure. For contractors, distributors, and construction companies, purchasing geotextiles wholesale offers not only cost efficiency but also access to consistent, high-quality materials suitable for a wide range of applications.

The Engineering Role of Geotextiles

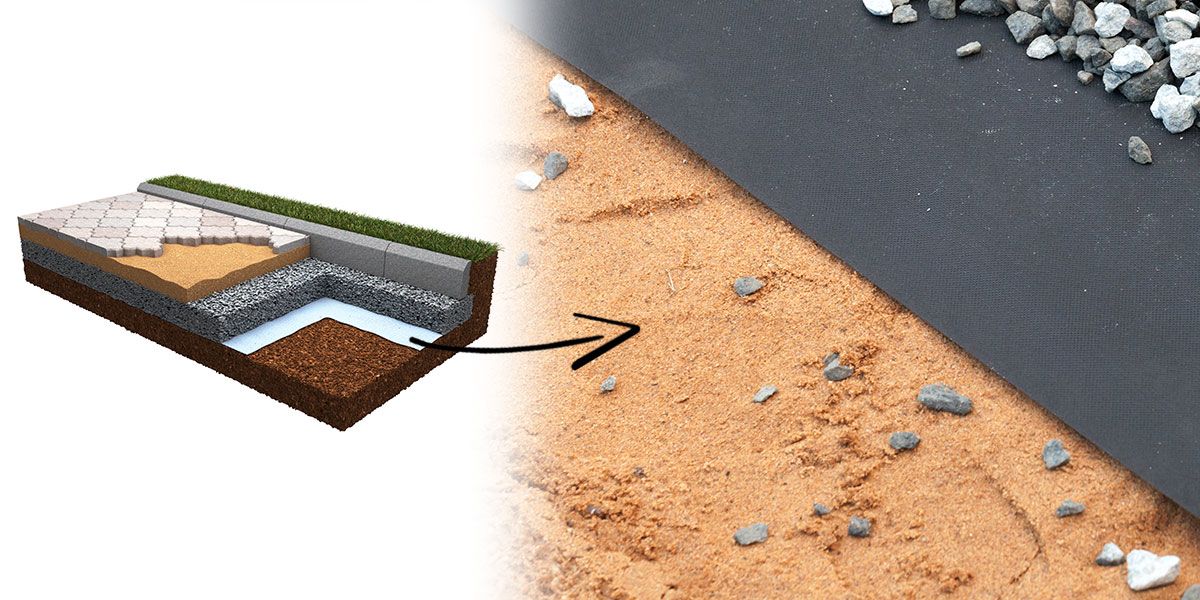

Geotextiles are synthetic fabrics made from polypropylene (PP) or polyester (PET). These permeable materials are designed to interact with soil, rock, and water to enhance mechanical and hydraulic performance. They are used beneath roads, embankments, railways, drainage systems, and landfills — quietly but powerfully supporting the world’s infrastructure.

The key functions of geotextiles include:

Separation: Prevents the mixing of different soil layers, maintaining the structural integrity of roads and pavements.

Reinforcement: Increases load-bearing capacity and distributes pressure evenly, preventing ground deformation.

Filtration and Drainage: Allows water to flow while retaining fine soil particles, ensuring proper hydraulic balance.

Protection: Shields geomembranes and waterproof liners from punctures, abrasion, and mechanical damage.

These combined properties make geotextiles essential in projects that require both soil stabilization and long-term durability.

Main Types of Geotextiles in the Wholesale Market

1. Nonwoven Geotextiles

Nonwoven geotextiles are made by bonding fibers through mechanical or thermal processes. They have excellent permeability and are ideal for applications where filtration and drainage are critical — such as in retaining walls, drainage trenches, and landfill capping systems.

Key advantages: high water flow rate, good flexibility, and superior protection against soil movement.

2. Woven Geotextiles

Woven geotextiles are manufactured by weaving polypropylene yarns into a strong, uniform fabric. Their high tensile strength and low elongation make them ideal for soil reinforcement, slope stabilization, and road base construction.

Key advantages: strong load distribution, dimensional stability, and resistance to UV and chemical degradation.

3. Composite Geotextiles

Composite geotextiles combine woven and nonwoven layers to deliver both strength and filtration. They are used in demanding applications where separation, drainage, and reinforcement are required simultaneously, such as highways, embankments, and bridge abutments.

Key advantages: multi-functional performance, improved load transfer, and enhanced filtration under pressure.

Why Buy Geotextiles in Bulk

Purchasing geotextiles wholesale is a strategic choice for industrial and construction companies managing multiple or large-scale projects. Wholesale supply ensures:

Consistent product quality from standardized manufacturing.

Lower unit cost through bulk production and logistics efficiency.

Flexible customization, including GSM, roll width, and polymer type.

Reliable delivery, crucial for time-sensitive infrastructure works.

Many wholesale manufacturers also provide technical documentation and performance data to meet international standards such as ISO, ASTM, and EN.

Applications Across Industries

The versatility of geotextiles allows them to be applied across multiple sectors:

Road and Railway Construction: Improves subgrade strength and prevents rutting.

Water Management Systems: Facilitates drainage in canals, reservoirs, and tunnels.

Landfills and Mining: Acts as a protective and filtration layer for geomembranes.

Coastal and Erosion Control: Stabilizes shorelines and prevents soil loss under hydraulic forces.

Agriculture and Landscaping: Used to control weeds, retain moisture, and prevent soil erosion.

Whether for geotechnical engineering or environmental protection, geotextiles serve as a practical, durable, and sustainable material for long-term soil management.

Conclusion

As infrastructure demands continue to grow, geotextiles wholesale supply provides a foundation of reliability for modern construction. Their ability to reinforce, protect, and separate soil layers makes them indispensable in every stage of project development.

For contractors and project managers seeking performance, cost efficiency, and durability, wholesale geotextiles are not just a material choice — they are a long-term investment in stability and sustainability.

FAQs

1. What are geotextiles made of?

They are primarily made from polypropylene (PP) or polyester (PET), offering high strength, durability, and resistance to environmental conditions.

2. What’s the difference between woven and nonwoven geotextiles?

Woven types are stronger and used for reinforcement, while nonwoven types are more permeable and ideal for filtration and drainage.

3. What are the typical applications of geotextiles?

They are used in roads, embankments, drainage systems, coastal protection, and landfill engineering.

Post time: Nov-07-2025