Effective drainage is a critical factor in the success of modern civil engineering, construction, and landscaping projects. Needle punch geotextile has become an ideal material for improving drainage system performance due to its durability, permeability, and reinforcement properties.

Whether in road construction, retaining walls, green roofs, or landfill drainage systems, understanding the applications and advantages of needle punch geotextile can help businesses optimize costs, extend infrastructure lifespan, and reduce long-term maintenance requirements.

Needle punch geotextiles serve as both a filtration and reinforcement layer, ensuring smooth water flow while maintaining soil stability. Their flexibility and durability make them a preferred solution for both large-scale engineering projects and landscaping applications.

What Is Needle Punch Geotextile?

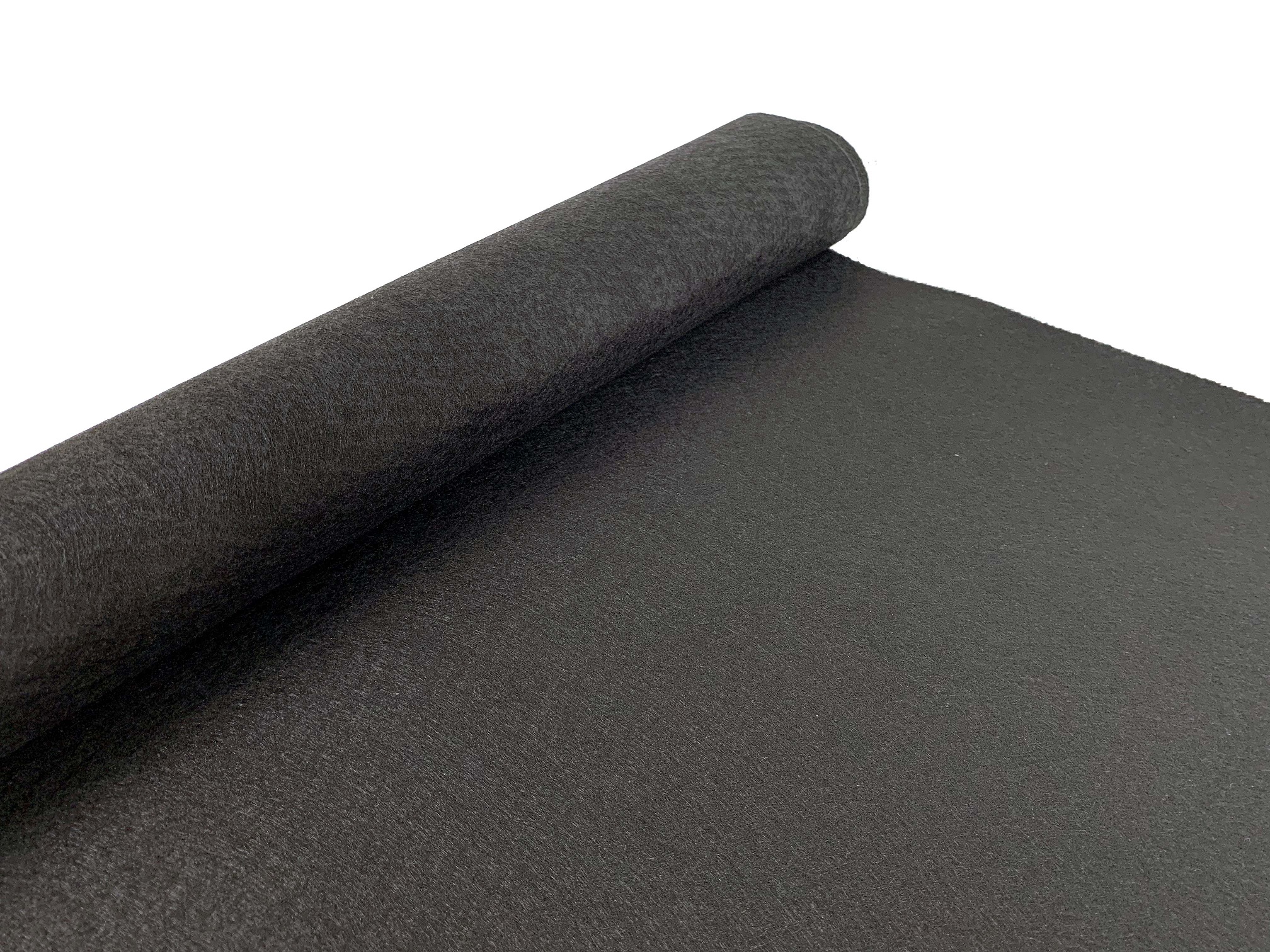

Needle punch geotextile is a type of nonwoven fabric manufactured by mechanically entangling synthetic fibers—typically polypropylene (PP) or polyester (PET)—using barbed needles. This process creates a dense, durable fiber network that resists tearing while allowing water to pass through.

Compared to woven geotextiles, needle punch geotextiles are highly flexible and conformable, making them suitable for uneven terrain and ensuring the continuity and functionality of drainage systems. Their combination of durability and permeability makes them ideal for both temporary and permanent drainage applications.

How Needle Punch Geotextiles Function in Drainage Systems

Needle punch geotextiles primarily serve as filtration and reinforcement layers in drainage systems. Their key functions include:

● Filtration: Retains fine soil particles while allowing water to flow freely.

● Separation: Prevents mixing of soil layers, maintaining the integrity of both the drainage layer and surrounding soil.

● Reinforcement: Enhances the load-bearing capacity of weak soils, reducing erosion and surface collapse risks.

● Protection: Shields drainage pipes or geomembranes from damage caused by sharp stones or soil movement.

Through these functions, needle punch geotextiles improve drainage network efficiency, reduce long-term maintenance costs, and extend infrastructure lifespan.

Typical Applications in Drainage Systems

Needle punch geotextiles are highly versatile and can be applied across various drainage scenarios:

● Road Construction: Placed under pavement layers to improve subgrade drainage and prevent water accumulation that can damage roads.

● Retaining Walls: Installed behind walls to allow water to escape while retaining soil particles, reducing hydrostatic pressure.

● Landfills and Waste Management: Serves as a protective layer for drainage layers, ensuring smooth leachate flow and safeguarding geomembranes.

● Green Roofs: Promotes water drainage while supporting soil and vegetation layers.

● Sports Fields and Landscaping: Prevents soil compaction while ensuring efficient water flow.

These applications demonstrate the adaptability of needle punch geotextiles in both large-scale civil engineering projects and smaller landscaping tasks.

Advantages of Needle Punch Geotextiles

Companies using needle punch geotextiles in drainage systems enjoy several benefits:

● Durability and Longevity: Resistant to punctures, UV exposure, and chemical degradation.

● Efficient Water Management: Prevents soil clogging and maintains consistent drainage flow.

● Cost-Effectiveness: Reduces the need for extensive excavation, gravel, or ongoing maintenance.

● Ease of Installation: Lightweight and flexible, allowing quick deployment over uneven terrain.

● Environmental Friendliness: Minimizes soil erosion and sedimentation, meeting sustainability standards.

Leveraging these advantages allows businesses to achieve efficient drainage while controlling costs and environmental impact.

How to Choose Needle Punch Geotextiles for Drainage

When selecting a needle punch geotextile for drainage systems, consider the following factors:

● Material Type: PP geotextiles offer chemical resistance and UV stability for outdoor applications, while PET geotextiles provide higher tensile strength and dimensional stability for heavy-duty projects.

● Thickness and Weight: Heavier fabrics provide better filtration and durability for high-load applications.

● Permeability: Ensure adequate water flow to meet drainage system design requirements.

● Project Scale: Industrial-grade fabrics are suitable for large projects, while standard grades can be used for smaller landscaping applications.

● Installation Environment: Consider soil type, slope, and traffic conditions when choosing specifications.

Proper selection ensures optimal performance and minimizes long-term maintenance.

Installation Tips for Drainage Systems

Proper installation is critical for needle punch geotextile performance:

● Surface Preparation: Remove debris, stones, and sharp objects to prevent fabric damage.

● Overlap Layers: Maintain at least 15–30 cm overlap between adjacent sheets to ensure continuous coverage.

● Secure Placement: Use stakes or pins to hold the fabric in place, especially on slopes.

● Protective Covering: Apply gravel or drainage aggregate over the fabric to protect it and enhance filtration.

Following these guidelines ensures durability and long-term stability of the drainage system.

Conclusion

Needle punch geotextiles provide reliable, cost-effective, and environmentally friendly solutions for drainage systems. Combining filtration, separation, reinforcement, and protection, they enhance drainage efficiency, extend infrastructure lifespan, and reduce maintenance costs. For B2B companies, selecting the right material, thickness, and installation method is crucial to achieving optimal drainage performance.

FAQ:

Q1: What is the difference between PP and PET needle punch geotextiles?

PP geotextiles are chemically resistant and UV stable, ideal for outdoor use, while PET geotextiles offer higher tensile strength and dimensional stability for heavy-duty projects.

Q2: Can needle punch geotextiles prevent soil clogging in drainage systems?

Yes, the fiber network allows water to pass while retaining fine soil particles, preventing pipe or channel blockage.

Q3: Are needle punch geotextiles suitable for both small and large-scale drainage projects?

Absolutely. They can be used in landscaping, green roofs, roads, retaining walls, and landfill drainage systems.

Q4: How long do needle punch geotextiles last in drainage applications?

High-quality PP or PET needle punch geotextiles can last 20–50 years with proper installation and protection, depending on environmental conditions and load exposure.

Post time: Feb-02-2026