In the world of industrial and commercial packaging, protection and efficiency are paramount.  This professional guide will explore why extruded netting has become an indispensable tool across a wide range of industries.

This professional guide will explore why extruded netting has become an indispensable tool across a wide range of industries.

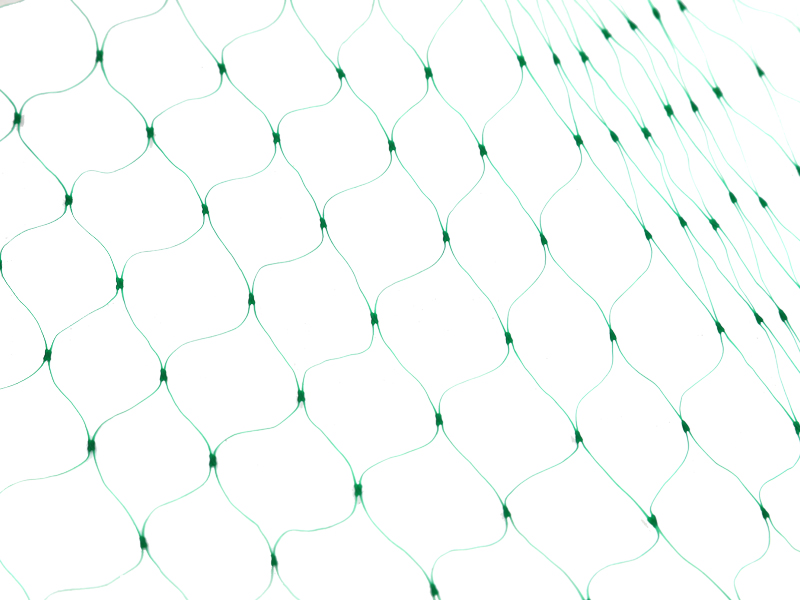

What is Extruded Netting?

Extruded netting is a mesh-like material created by forcing molten polymer through a die. Unlike woven nets, which can unravel, extruded netting is made from a single, continuous strand, making it exceptionally strong, lightweight, and durable. Its uniform structure and flexibility allow it to conform to a variety of shapes and sizes, making it an ideal solution for countless applications.

Key Applications Across Industries

The unique properties of extruded netting make it a go-to solution for businesses in diverse sectors. Here are some of the most common applications:

Packaging & Protection:

Produce & Food: Its soft, flexible nature makes it perfect for packaging fruits and vegetables like onions and citrus. The open mesh allows for breathability, extending product shelf life.

Industrial Components: Used as a protective sleeve for delicate metal or plastic parts, preventing scratches and dings during shipping and handling. This is vital for industries like automotive, aerospace, and machinery.

Filtration & Separation:

Aquaculture: Netting is used to create cages for fish farming, providing a durable barrier that allows for water flow and nutrient exchange.

Water Treatment: Used in filtration systems to separate solids from liquids in industrial and municipal processes.

Structural Support & Reinforcement:

Erosion Control: The netting is laid over newly seeded ground to stabilize soil and prevent erosion from wind and rain.

Composite Reinforcement: Used in manufacturing as a core material to add strength and structure to composite products.

Why Choose Extruded Netting?

Beyond its wide range of applications, extruded netting offers distinct advantages for B2B operations:

Cost-Effectiveness: It is generally more affordable to produce than woven or knitted materials, providing a high-value solution for bulk purchasing.

Superior Durability: The single-strand construction means it won’t fray, unravel, or tear easily, ensuring reliable performance in demanding environments.

Lightweight & Flexible: This makes it easy to handle and store, reducing shipping weight and adapting to irregularly shaped products.

Recyclability: Many extruded nettings are made from recyclable polymers, aligning with corporate sustainability goals and reducing environmental impact.

Extruded netting is a powerful and versatile material that solves a wide array of industrial challenges. Whether you’re in need of a protective packaging solution, a robust filtration medium, or a lightweight structural component, this technology offers a durable, cost-effective, and adaptable choice. By integrating extruded netting into your operations, you can enhance product integrity, streamline processes, and gain a competitive edge.

FAQ

Q1: What materials are used to make extruded netting? A: Extruded netting is most commonly made from polymers like high-density polyethylene (HDPE), polypropylene (PP), or low-density polyethylene (LDPE).

Q2: Is extruded netting safe for food contact? A: Yes, many grades of extruded netting are specifically manufactured to be FDA-approved and safe for direct contact with food products.

Q3: Can extruded netting be customized? A: Absolutely. It can be customized in terms of color, mesh size, thickness, and even material type to meet specific application requirements.

Post time: Aug-18-2025