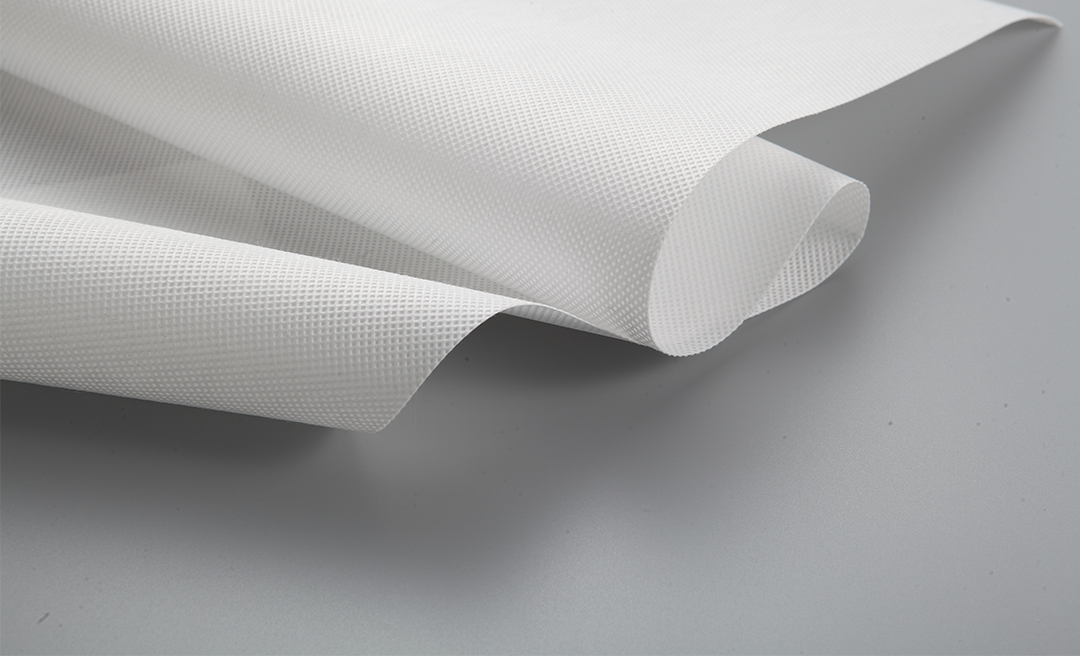

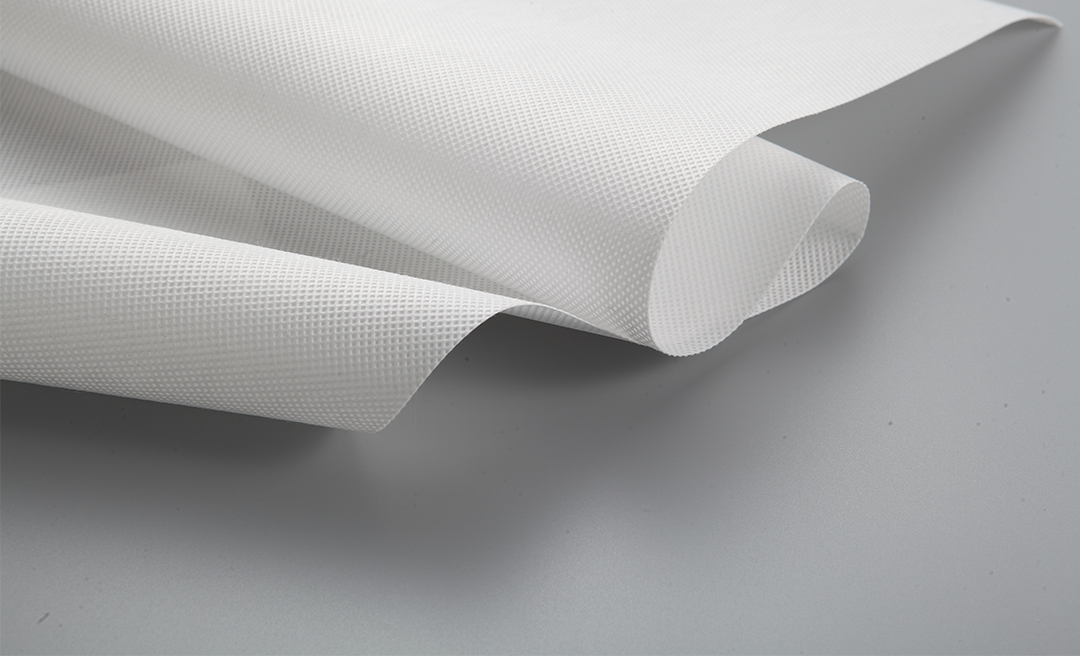

The pet spunbond nonwoven market is experiencing significant growth and presents substantial opportunities for businesses across various sectors. This versatile material, known for its strength, durability, and cost-effectiveness, is increasingly replacing traditional textiles and other nonwoven alternatives in a wide range of applications. Understanding the key trends and drivers shaping this market is crucial for B2B stakeholders looking to leverage its potential.

y Properties and Advantages of PET Spunbond Nonwovens

Polyethylene terephthalate (PET) spunbond nonwovens offer a unique combination of properties that make them highly desirable for numerous industrial and consumer applications.

High Strength and Durability: PET fibers exhibit excellent tensile strength and resistance to tearing and puncture, ensuring longevity and reliability in demanding applications.

Chemical Resistance: PET is resistant to many chemicals, including acids and alkalis, making it suitable for use in environments where chemical exposure is a concern.

Thermal Stability: PET spunbond nonwovens can withstand relatively high temperatures, expanding their applicability in various industrial processes.

Moisture Resistance: PET fibers are hydrophobic, providing good resistance to moisture and preventing water absorption.

Breathability: Depending on the manufacturing process, PET spunbond nonwovens can be engineered to offer varying levels of breathability.

Cost-Effectiveness: Compared to some other nonwoven materials and traditional textiles, PET spunbond nonwovens often offer a more economical solution without compromising performance.

Recyclability: PET is a recyclable material, aligning with growing sustainability initiatives and offering end-of-life options.

Key Applications Driving Market Growth

The versatility of PET spunbond nonwovens has led to their widespread adoption across diverse industries. Some of the key application areas driving market growth include:

Hygiene Products: Used as top sheets, back sheets, and acquisition-distribution layers (ADL) in diapers, sanitary napkins, and incontinence products due to their softness, liquid permeability, and strength.

Medical and Healthcare: Employed in surgical drapes, gowns, sterilization wraps, and wound dressings for their barrier properties and breathability.

Agriculture: Used as crop covers, weed barriers, and greenhouse shading to enhance crop yields and protect plants.

Construction: Utilized in roofing membranes, insulation facings, and drainage layers due to their durability and water resistance.

Filtration: Used in air and liquid filtration systems for their excellent particle retention and flow properties.

Packaging: Employed in industrial packaging, garment bags, and protective coverings due to their strength and tear resistance.

Geotextiles: Used for soil stabilization, erosion control, and drainage in civil engineering projects.

Automotive: Found in car covers, interior trim, and filtration systems due to their durability and cost-effectiveness.

Factors Influencing the PET Spunbond Nonwoven Market

Several factors are contributing to the growth and evolution of the PET spunbond nonwoven market:

Increasing Demand from End-Use Industries: The expanding applications of PET spunbond nonwovens across hygiene, medical, agriculture, and construction sectors are fueling market growth.

Growing Awareness of Hygiene and Healthcare: Rising health consciousness and stringent hygiene standards are driving the demand for disposable nonwoven products.

Focus on Sustainability: The recyclability of PET aligns with the increasing emphasis on sustainable materials and circular economy initiatives.

Technological Advancements: Innovations in spunbond technology are leading to the development of PET nonwovens with enhanced properties and functionalities.

Cost Advantages: In many applications, PET spunbond nonwovens offer a cost-effective alternative to traditional materials.

Infrastructure Development: Growing infrastructure projects, particularly in developing economies, are increasing the demand for geotextiles made from PET spunbond nonwovens.

Conclusion

The pet spunbond nonwoven market is poised for continued expansion, driven by its unique properties, diverse applications, and favorable market trends. For businesses operating in or looking to enter this space, understanding the key drivers and emerging applications is essential for capitalizing on the significant growth opportunities available. The versatility and cost-effectiveness of PET spunbond nonwovens make them an increasingly attractive material across a wide range of industries.

FAQ

Q1: What are the primary advantages of using PET spunbond nonwovens compared to other nonwoven materials? A: PET spunbond nonwovens typically offer a superior combination of strength, durability, chemical resistance, and cost-effectiveness compared to many other nonwoven alternatives. Their recyclability is also a significant advantage in today’s market.

Q2: Which end-use industry currently accounts for the largest share of the pet spunbond nonwoven market? A: The hygiene industry (including diapers, sanitary napkins, and incontinence products) is currently one of the largest end-use segments for PET spunbond nonwovens globally.

Q3: How is the increasing focus on sustainability impacting the PET spunbond nonwoven market? A: The recyclability of PET spunbond nonwovens is a significant advantage in light of increasing sustainability concerns. This is driving demand for PET nonwovens as companies seek more environmentally friendly material options.

Q4: What are some emerging trends in the technology and application of PET spunbond nonwovens? A: Emerging trends include the development of finer denier PET fibers for softer and more flexible nonwovens, advancements in spunbond technology to enhance barrier properties and breathability, and the exploration of new applications in areas like filtration and advanced composites.

Post time: Aug-20-2025