In the world of industrial and commercial applications, the right material can significantly impact a product’s performance, cost, and overall design. Extruded netting manufacturers are at the forefront of providing a versatile, lightweight, and durable solution used across countless industries. From packaging and filtration to construction and agriculture, extruded netting offers a unique blend of properties that make it an invaluable component. For businesses looking to optimize their processes and create innovative products, choosing the right manufacturing partner is a strategic decision.

The Key Advantages of Extruded Netting in B2B Applications

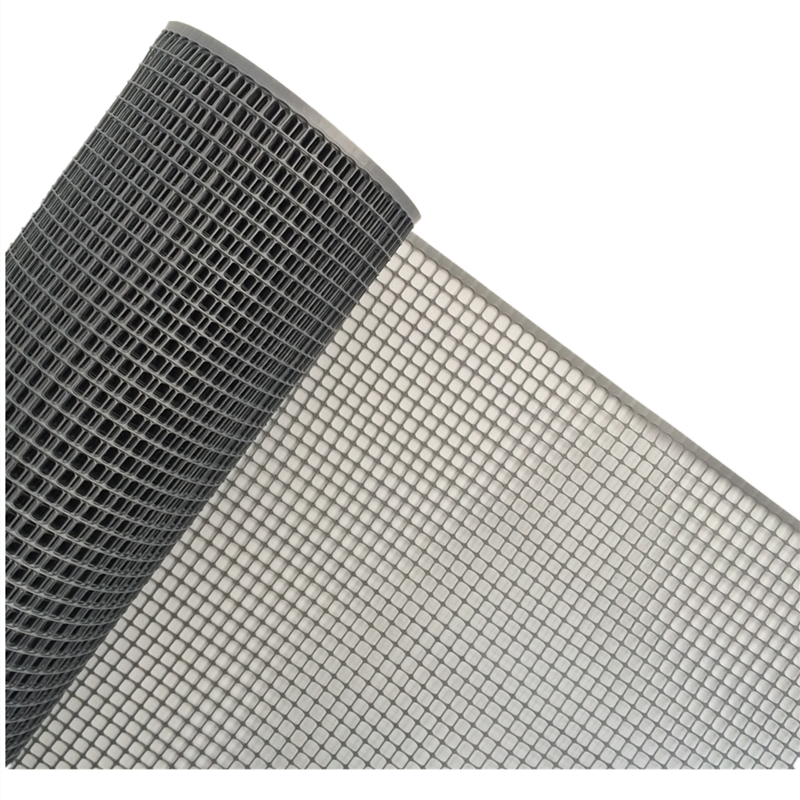

Extruded netting is not a one-size-fits-all product; its value lies in its adaptability and superior performance characteristics, which make it a go-to choice for diverse business needs.

- Exceptional Versatility: Extruded netting can be produced in a wide array of mesh sizes, shapes, thicknesses, and colors. This versatility allows manufacturers to create a custom solution for almost any application, whether it’s for delicate product packaging or robust industrial separation.

- High Strength-to-Weight Ratio: Despite being incredibly lightweight, extruded netting is remarkably strong and tear-resistant. This makes it an ideal material for protective wraps, support structures, and containment systems where minimizing weight is crucial without sacrificing durability.

- Cost-Effectiveness: The extrusion process is highly efficient, allowing for large-scale production at a low cost. This makes extruded netting a budget-friendly option for both high-volume packaging and industrial applications, providing a strong return on investment.

- Chemical and Environmental Resistance: Made from various polymers like polyethylene and polypropylene, extruded netting is resistant to many chemicals, moisture, and UV radiation. This makes it suitable for use in harsh environments and for products that require long-term stability.

-

How to Choose the Right Extruded Netting Manufacturers

Finding the perfect partner is about more than just finding a supplier; it’s about finding a collaborator who understands your specific needs and can deliver a consistent, high-quality product.

- Customization Capabilities: The best manufacturers have the expertise to customize every aspect of the netting, from the polymer and strand diameter to the mesh pattern and roll dimensions. Look for a partner who can provide tailor-made solutions rather than just standard off-the-shelf products.

- Quality Control and Certifications: High-quality manufacturing is non-negotiable. Verify that the extruded netting manufacturers you consider adhere to strict quality control standards. Inquire about their certifications (e.g., ISO) and their process for ensuring product consistency and reliability.

- Material Science Expertise: A deep understanding of polymer science is key. The right manufacturer can guide you on choosing the best material for your application, whether you need a netting that is food-safe, UV-stabilized, or highly chemical-resistant.

- Supply Chain Reliability: In a B2B setting, a dependable supply chain is critical. Ensure your potential partner has a proven track record of on-time delivery, efficient logistics, and the capacity to meet your production demands consistently, even with large or custom orders.

Conclusion: A Strategic Partner for Innovation

In an increasingly competitive market, the right materials can give your business a decisive advantage. Partnering with a leading extruded netting manufacturer is a strategic move that goes beyond a simple transaction. It is a collaboration that provides access to custom-engineered solutions, technical expertise, and a reliable supply chain. By making an informed choice, you can enhance the quality of your products, optimize your operational costs, and drive innovation within your industry.

Frequently Asked Questions

Q1: What are the main differences between extruded and woven netting? A1: Extruded netting is a single-piece, seamless product created by forcing molten polymer through a die. Woven netting is made by interlacing strands of material. Extruded netting is generally stronger, more rigid, and more cost-effective for large-scale production.

Q2: What are some common applications for extruded netting? A2: Extruded netting is used for a wide range of applications, including protective packaging for bottles and machinery, support nets for agricultural plants, filtration systems for air and liquids, and reinforcement grids for construction projects.

Q3: How do manufacturers customize extruded netting? A3: Customization can involve adjusting the polymer type (e.g., PE, PP), the mesh size and pattern (e.g., diamond, square), strand diameter, color, and even adding special properties like UV resistance or flame retardancy to meet specific project requirements.

Post time: Aug-11-2025