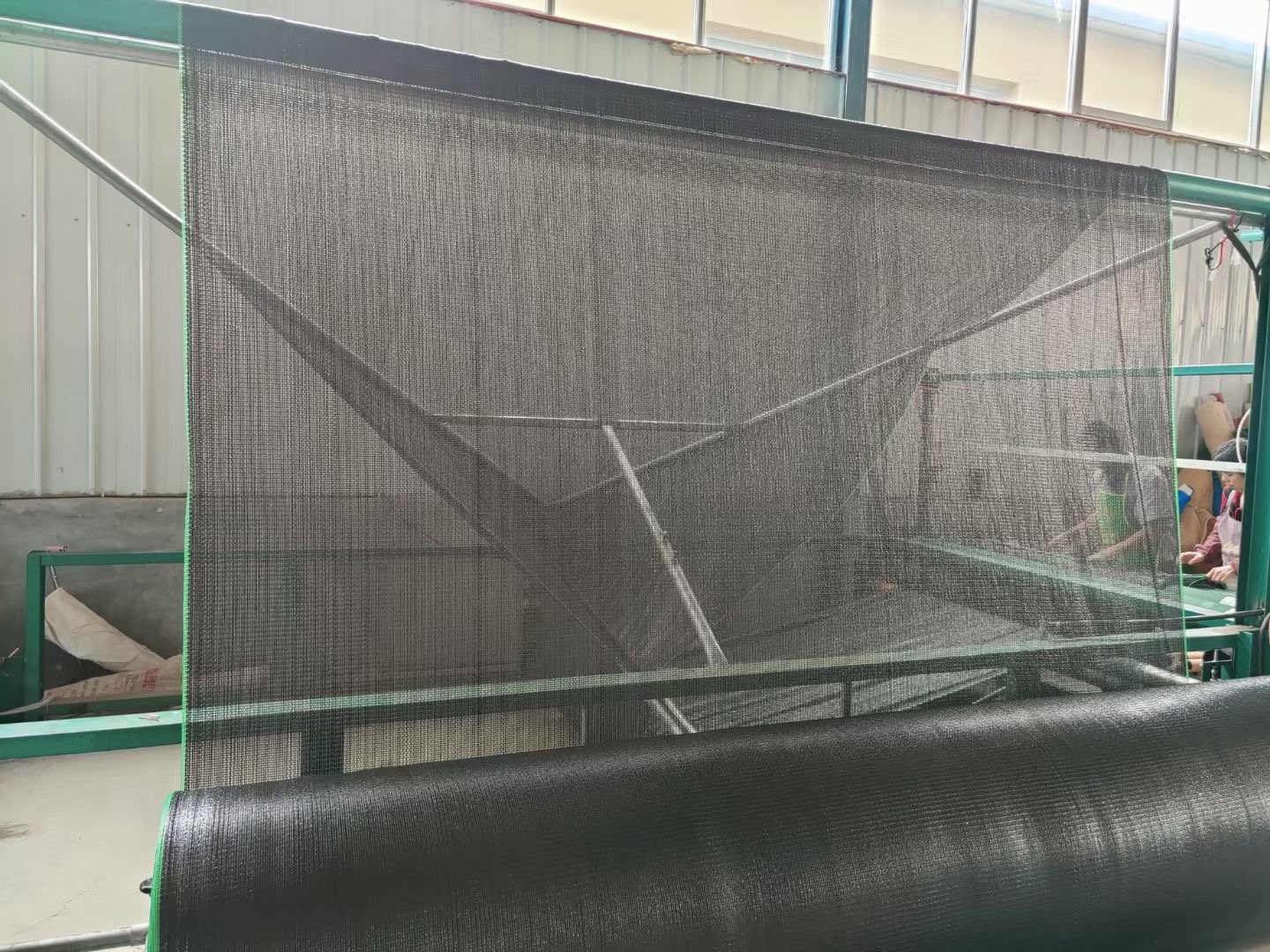

In today’s global market, the demand for high-quality shade cloth is skyrocketing. From agricultural protection to commercial building projects and residential landscaping, shade cloth provides essential UV protection, temperature control, and a barrier against wind and hail. For businesses that manufacture these products, the key to success lies in production efficiency, quality consistency, and operational reliability. This is where our advanced shade cloth making machine becomes more than just equipment—it’s the core of a profitable and sustainable manufacturing operation.

Why Our Machine Is a Game-Changer

Our machine is engineered to address the most critical challenges faced by manufacturers today. It’s not just about speed; it’s about a comprehensive solution that improves every aspect of the production process.

1. Unmatched Production Efficiency and Speed

High-Speed Knitting: Equipped with a high-performance knitting head and an advanced control system, our machine operates at exceptional speeds, significantly increasing your daily output. This allows you to meet high-volume orders and reduce lead times.

Continuous Operation: The machine is designed for 24/7 operation with minimal downtime. Features like automatic lubrication and a robust, low-vibration frame ensure consistent, uninterrupted production.

2. Superior Product Quality and Versatility

Precision Control: Our machine offers precise control over weave density, yarn tension, and pattern, allowing you to produce a wide range of shade cloths with varying densities (e.g., 30%, 50%, 70%, 90%) to meet diverse market needs.

Versatile Material Handling: It is compatible with a variety of materials, including HDPE (High-Density Polyethylene) flat yarn and monofilaments. This versatility enables you to manufacture products for different applications, from agricultural netting to privacy screens and safety fences.

3. Smart Technology for Seamless Operations

Automated Functions: The integrated electronic control panel simplifies operation, while features like photoelectric sensors automatically detect yarn breaks and stop the machine to prevent defects and minimize material waste.

Remote Monitoring and Support: Our machine comes with remote monitoring capabilities, allowing you to track production data and machine status from anywhere. This also enables our technical team to provide instant remote support, ensuring your operations remain smooth.

Conclusion: A Strategic Investment for Your Business

Investing in our shade cloth making machine is a strategic decision that goes beyond a simple equipment purchase. It’s an investment in your company’s future, offering a direct path to higher profitability, superior product quality, and enhanced competitiveness. By leveraging its advanced technology, you can streamline your production, reduce operational costs, and solidify your position as a leading provider of high-quality shade cloth.

FAQ

Q1: What kind of yarns can this machine use?

A1: Our machine is highly versatile and can use a range of materials, including HDPE flat yarn and monofilaments, to produce different types of shade cloth and netting.

Q2: How does the machine help reduce production costs?

A2: By offering high-speed production, minimizing material waste through smart sensors, and ensuring continuous operation with low maintenance, the machine significantly reduces your overall production costs per unit.

Q3: Can the machine produce different shade densities?

A3: Yes, the machine’s precision control system allows you to easily adjust settings to produce shade cloth with various densities, from low-density agricultural nets to high-density privacy screens.

Q4: Do you offer installation and training?

A4: Yes, we provide a complete solution, including on-site installation, commissioning, and comprehensive training for your operators to ensure they can use the machine efficiently and safely from day one.

Post time: Aug-25-2025